Rely on , Your Dense-Pack Building Science Experts

Nobody understands the science of building better Pole Barns than . If you want to create a thermally efficient and air tight space, it's not enough just to insulate. You must choose the right insulation and air sealing system for your walls, and be sure it's properly installed.CLICK FOR DETAILS

LET. US. HELP.

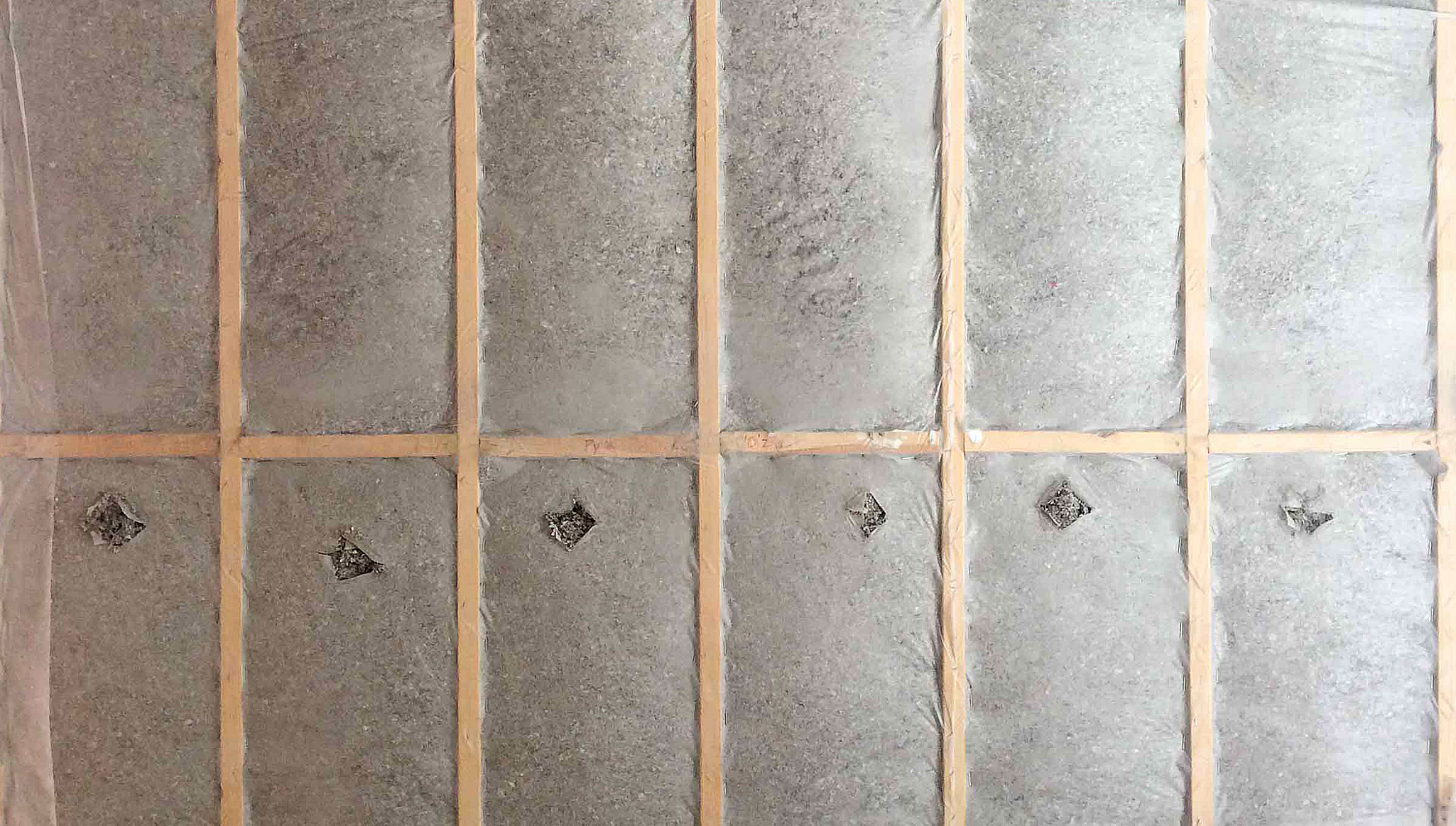

Dense-Pack Wall Insulation

When cellulose is pneumatically installed at high velocity to densities greater than 3.5 pounds per square foot, it acquires a unique air sealing property. In this process, the material behaves as a liquid, flowing into obscure bypasses and solidifying them.

Dense packing (DP) solves air movement problems critical to building performance that would be impractical to access or repair in any other way. So it is a pillar of weatherization practice and indispensable to the revitalization of old buildings.

Building cavities subjected to wind, stack, or mechanical pressure move enormous amounts of conditioned air. Common insulation methods do little to stop this flow, so the insulation performance is degraded, and the larger convective heat losses continue. DP forms a perfect injection molded block in these cavities that stops the air movement and delivers real control of conductive heat loss too.

Tolerance to compaction is a critical property of cellulose. Unlike mineral based insulations, organic fiber is cellular in nature and inherently non-conductive. Trapped air is only one part of its insulating ability. Compacting cellulose insulation would ultimately reduce its R-value to that of wood. If we compact fiberglass to the same degree, we would get the insulation performance of glass. When we need to get air sealing by tightly packing insulation, cellulosic fibers such as cotton and paper retain their resistance to conduction and mineral fibers don't.

Building cavities are dense packed by inserting a pipe, tube, or hose down the entire length of the passage. A powerful insulation blower delivers a lean mixture of cellulose and air at about a hundred feet per second. Initially the cavity is pressurized with a cloud of insulation. The air flows out through every crack and pinhole carrying fine particles of insulation. The holes are clogged with insulation until they stop flowing and the cavity fills with a loose pile. Then the cellulose chunks charging down the tube start to slam into the loose pile and pack it. When it becomes very tight, it plugs the end of tube and stalls the insulation blower. The tube is quickly pulled back until the tip finds more loose insulation. The flow and packing process starts again and this continues until the entire cavity is solid.

Now this part of the building shell is an efficient part of the thermal envelope. The area is insulated to a real R-3.8 per inch because there is a real pressure barrier built into the assembly to stop air flow and protect the insulation.

Thermal renovations to old buildings typically produce startling changes in performance. The effective leakage area in old houses is typically reduced by 40-70 percent just by dense packing the hidden framing bays. This results in actual ventilation reductions of 50-90%. Tremendous fuel reductions result. But the collateral improvements are often more important. Buildings that were formerly impossible to heat now become stable, comfortable and highly efficient living and working spaces.

Thermal revitalization is fundamental to the historic preservation of old buildings. DP is an invisible and completely reversible process. With no diffusion barrier to trap moisture, it helps to preserve the shell of the building. Cellulose fiber is highly absorbent and actually wicks moisture content out of framing members. The pack imparts an enormous moisture storage capacity to the shell. This stabilizes the interior plaster and exterior paint by buffering the water load forced into the shell through the heating season. And by blocking all the paths for warm, moist air to blow into the framing spaces, they are relieved of 98% of the load right from the start.

DP insulation is an important element in fire safety. Typically, fire destroys wood buildings by entering and traveling through the framing bays. Once walls start to act like chimneys, the studs are quickly consumed. Blocking or fire stops are known to be effective in preventing the spread of fire from floor to floor and ultimately into the attic. DP behaves as continuous blocking in walls because the framing is really solid. In fact, test buildings with DP walls are virtually impossible to destroy by fire.

Not all buildings are good candidates for insulation including DP. Insulation should not be placed in contact with the soil, exterior masonry, unrated lighting fixtures, obsolete wiring, unlined or deteriorated chimneys, or leaking pipes and roofs. In general, all of the structural and mechanical defects must be repaired before a building is insulated.

Why Choose Us?

- Constant Owner interaction means no project manager or multiple people trying to make decisions.

- The highest quality products and with many small details that often go unnoticed by other contractors, let's take your insulation project to the next level.

- Quality Control. The owner is hands on throughout the project, if any problems or issues arise they can be dealt with immediately.

- Nonstop communication - The key to the success of your project is good communication. And, a big part of communication is listening. From the beginning of a project to its end, our company places a high priority on listening - to you, your needs and wishes.

- Solid Science - Our Building Science experts understand the principles of heat, air and moisture flow, and how the building envelope interacts with a building's mechanical systems as well as its occupants.